Degassing simulation using OpenFOAM

Space limitations and high cost pressure ultimately lead to hydraulic tanks becoming increasingly complex and smaller. This leads to a dramatic reduction in air separation in the tank – and thus to an increased amount of free air in the hydraulic system.

In hydraulic systems, free air is still a technical challenge today. As long as the air is dissolved in the oil, it does not change its properties.

On the other hand, undissolved air, d. H. Air bubbles, cause:

- Corrosion on pumps and controls

- Reduce the efficiency of pumps and hydraulic motors mincreased compressibility and thus possible stuttering movements of the output member

- Accelerated oil aging

- varnish noise

- Damage to the components (e.g. cavitation)

- etc.

The air gets into the circuit during assembly work, through leaks in the negative pressure area and when the oil flows back into the container. Depending on the separation capacity of the filter-tank system, the air in the tank rises only slowly and is sucked in again by the pump.

Simulation of air-liquid devices

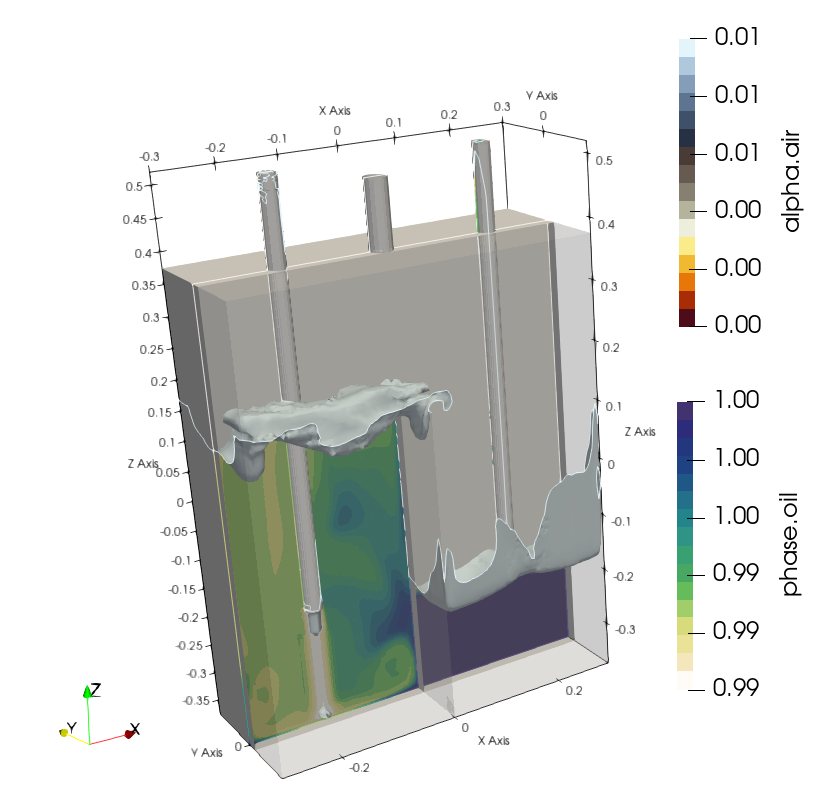

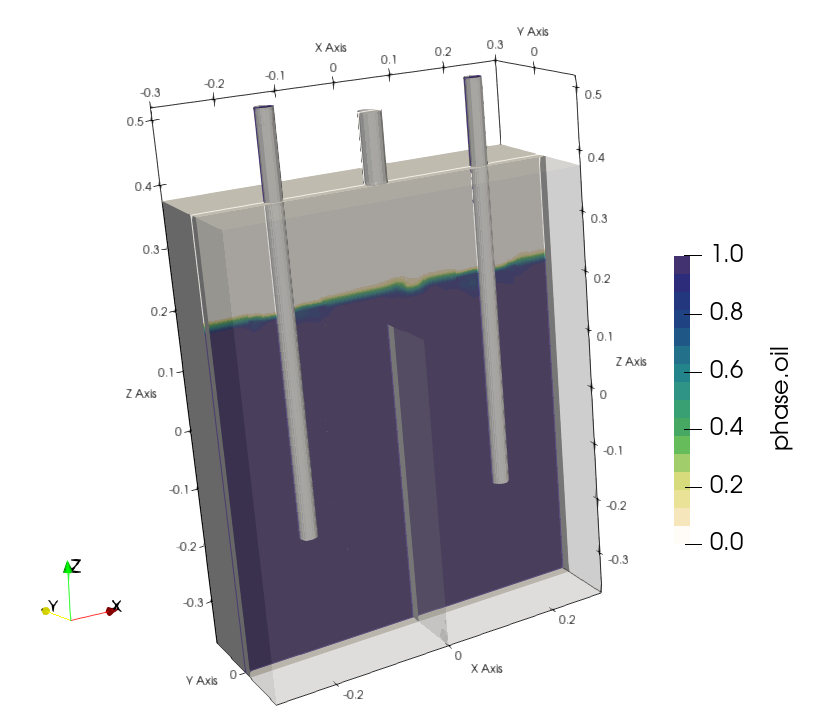

Silentdynamics uses InsightCAE to perform a number of simulations of dispersed gas bubbles in a degassing tank. Application of the solver twoPhaseEulerFoam enables the transient tracking of the gas phase, integral values of air at the outlets and overall the quality of the degassing device.

As example a simple degassing example is presented . One inlet and two oulets including a wear at the center. Oil-gas mixture move over the wear for degassing.

Setting up gas-oil dispersion boundary conditions as gas bubble size, blending coefficients, phaseProperties, etc. the simulation using twoPhaseEulerFoam could be initiated.

Using advanced solver settings within the framework InsightCAE, large time steps are enabled to mangage simulations in a reasonable time.

Isosurfaces of 1% gas are presented.

Changing of degassing tank geometry using numerical simulation leads to a sufficient degassing process of the hydraulic oil.