Author: hk

-

Exporting von STEP Dateien mit benannten Oberflächen aus PTC CREO

When preparing geometry for numerical simulations, it is often required to mark individual surfaces in the model. These surfaces can then be used e.g. as an inlet or forces and pressures can be applied in a structural simulation. The STEP format supports named entities. The question is: how to set the names in the CAD…

-

Vektoranalysis in der Bash Shell

When performing preparatory operations for e.g. CFD or FEM analyses, it is often necessary to specify vector parameters. Vector constants are easy to handle: DIR=“1 0 0″ myMesh –direction „$DIR“ However, it quickly becomes complicated if the vectors have to be manipulated, e.g. multiplied by scalars or rotated. A powerful solution is to use the…

-

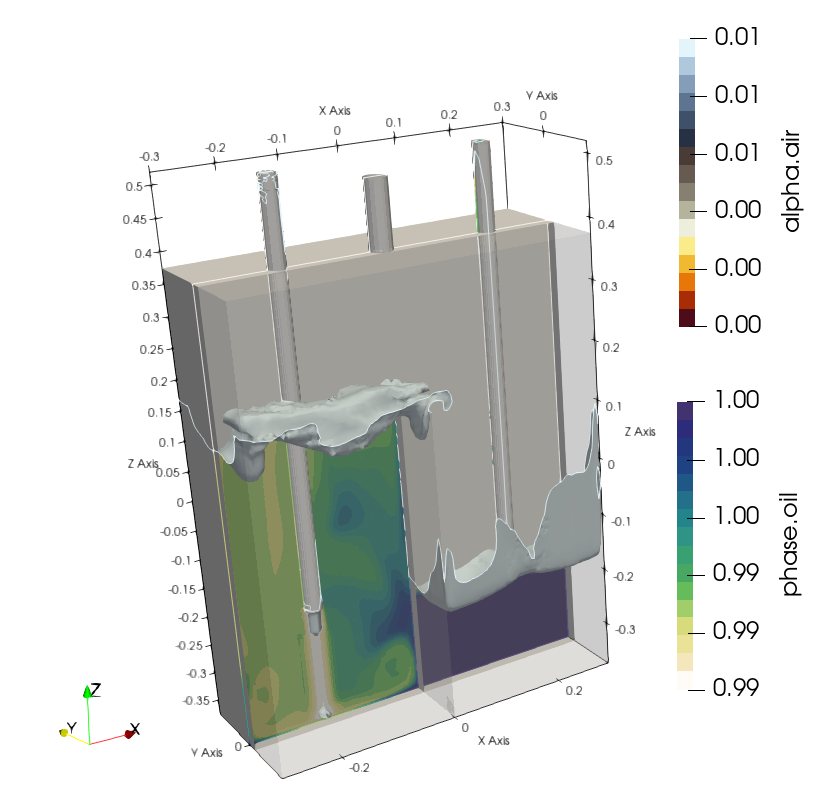

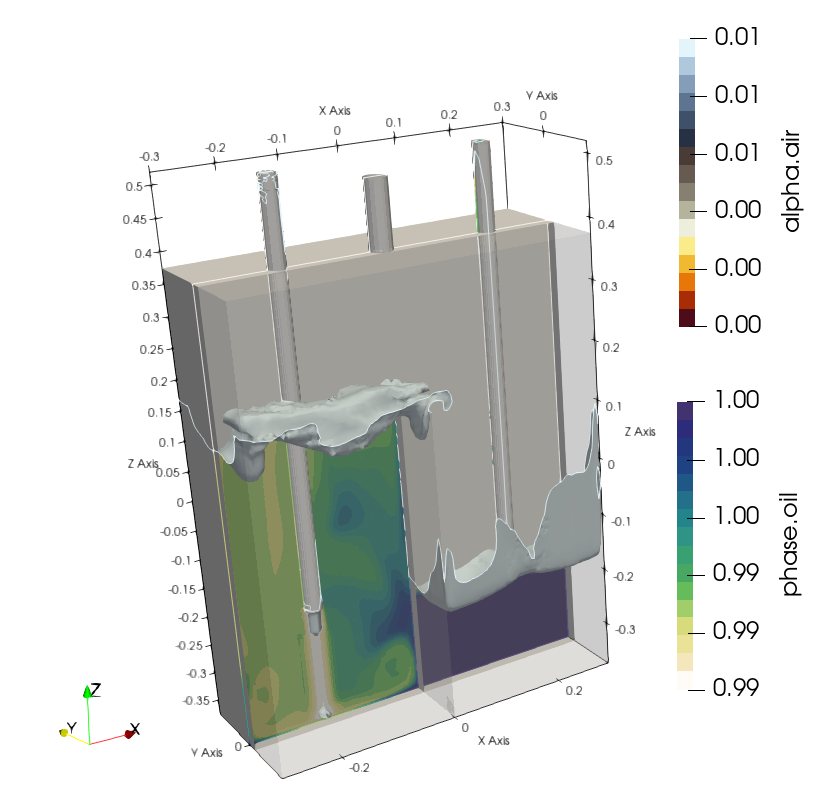

Simulation der Entgasung von Flüssigkeiten mit OpenFOAM

Platzmangel und hoher Kostendruck führen letztlich dazu, dass Hydrauliktanks immer komplexer und kleiner werden. Dies führt zu einer drastischen Verringerung der Luftabscheidung im Tank – und damit zu einem erhöhten Anteil an freier Luft im Hydrauliksystem. In hydraulischen Systemen ist die freie Luft auch heute noch eine technische Herausforderung. Solange die Luft im Öl gelöst…

-

Simulation Elektronik Kühlung mit OpenFOAM

Der begrenzte Platz und die hohe Leistungsaufnahme führen schließlich zu einem innovativen Kühlungsdesign für eine breite Palette von Leiterplatten. Die Anordnung der Stromversorgungen, die Abmessungen der Kühlkörper und das Design des Außengehäuses gewinnen an Bedeutung. Thermische Simulationen während des Entwurfsprozesses von Leiterplatten helfen, Überhitzungsprobleme in der späteren Produktionsphase zu vermeiden. Unterschiedliche Materialien, die Kombination von…

-

Electronic cooling simulation using OpenFOAM

Space limitations and high power supply ultimately lead to innovativ cooling design for a wide range of PCB. The arrangement of the power supply’s, heat sink dimensions and design of the outer housing become more important. Thermal simulations within in the design process of PCB help to overcome overheating problems in the later production stage. …

-

Degassing simulation using OpenFOAM

Space limitations and high cost pressure ultimately lead to hydraulic tanks becoming increasingly complex and smaller. This leads to a dramatic reduction in air separation in the tank – and thus to an increased amount of free air in the hydraulic system. In hydraulic systems, free air is still a technical challenge today. As long…

-

Vector Calculus in Bash Scripts

When performing preparatory operations for e.g. CFD or FEM analyses, it is often necessary to specify vector parameters. Vector constants are easy to handle: DIR=“1 0 0″ myMesh –direction „$DIR“ However, it quickly becomes complicated if the vectors have to be manipulated, e.g. multiplied by scalars or rotated. A powerful solution is to use the…

-

Exporting a STEP file with named surfaces from PTC Creo

When preparing geometry for numerical simulations, it is often required to mark individual surfaces in the model. These surfaces can then be used e.g. as an inlet or forces and pressures can be applied in a structural simulation. The STEP format supports named entities. The question is: how to set the names in the CAD…

-

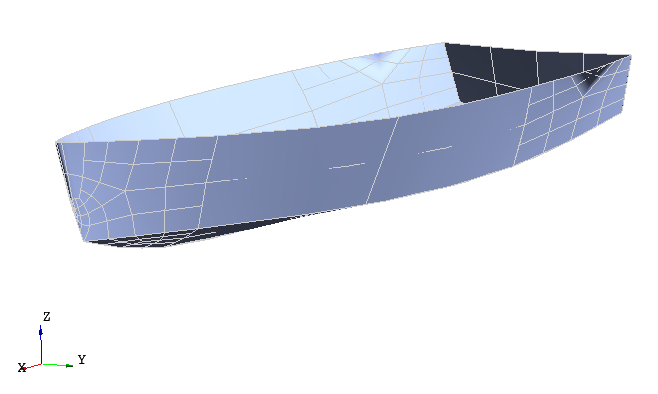

Importing IGES File (*.IGS) from FreeShip to OpenCASCADE

How to fix IGES import of FreeShip-generated geometry.